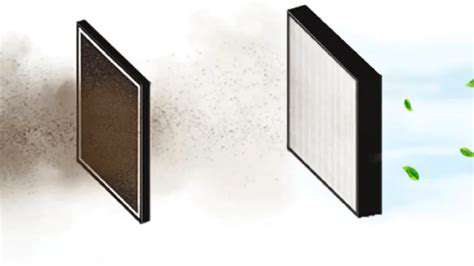

an incredibly dense web of fibers that stops contaminants in their tracks.The Filtration Process

Air purification through a HEPA filter isn't just simple straining - it's a sophisticated physical ballet. As air molecules dance through the filter, larger particles crash directly into fibers (imagine bugs hitting a windshield). Medium-sized particles get caught in the fibers' electrostatic pull, while the smallest particles wander aimlessly until they too eventually collide with a fiber. This three-stage capture mechanism explains why these filters are so effective across such a wide range of particle sizes.

The process is entirely mechanical, which means it works consistently without needing chemical treatments or electronic assistance. This reliability makes HEPA technology particularly valuable in critical environments like hospitals and clean rooms.

HEPA Filter Efficiency

When we talk about HEPA efficiency, we're discussing some of the most demanding performance standards in filtration. True HEPA filters must capture at least 99.97% of 0.3 micron particles - a size chosen because it represents the most challenging particle to catch. This benchmark isn't arbitrary; particles of this size tend to follow air currents most easily, slipping past lesser filters with ease.

Some specialized versions go even further, with ratings like H13 or H14 indicating even higher capture rates. These ultra-high-efficiency models are what you'll find protecting sensitive electronics during manufacturing or maintaining sterile conditions in pharmaceutical production.

Types of HEPA Filters

The HEPA family includes several specialized members, each optimized for different scenarios. Residential models prioritize quiet operation and energy efficiency, while industrial versions might emphasize durability and high airflow capacity. Medical-grade HEPA filters often incorporate additional safeguards against microbial growth, recognizing their use in infection control.

What many consumers don't realize is that HEPA-type or HEPA-like filters don't meet the same rigorous standards as true HEPA filters. This distinction matters greatly when selecting filters for health-sensitive applications like asthma management or post-surgical home care.

HEPA Filters and Air Quality

The impact of proper HEPA filtration on indoor air quality can be dramatic. Studies in homes with allergy sufferers show measurable reductions in symptoms after installing high-quality HEPA systems. For urban dwellers, these filters can reduce indoor particulate pollution by 50-90%, effectively creating cleaner air inside than exists outside.

Their value extends beyond just particle removal. By continuously cleaning recirculated air, HEPA filters gradually reduce the overall particle load in an environment, leading to cumulative benefits over time. This makes them particularly effective for managing chronic respiratory conditions.

HEPA Filters in Various Applications

While most people encounter HEPA filters in home air purifiers, their professional applications are even more impressive. Modern semiconductor factories couldn't operate without them - a single dust particle can ruin a microchip. NASA uses HEPA technology to maintain sterile conditions for spacecraft assembly. Even the automotive industry relies on them for paint booth ventilation.

Perhaps most crucially, HEPA filters form the last line of defense in hospital isolation rooms, protecting both patients and staff from airborne infections. Their ability to remove virus-containing droplets from the air has made them invaluable during recent global health crises.

Choosing the Right HEPA Filter for Your Home

Understanding HEPA Filter Technology

True HEPA filtration represents a specific performance standard, not just a marketing term. When evaluating options, look for documentation showing the filter meets either the U.S. DOE standard (for military/nuclear applications) or the more common EN 1822 standard. This verification matters because some filters labeled HEPA-style may capture as little as 85% of particles at 0.3 microns - far below true HEPA performance.

The best residential models now incorporate smart features like particle sensors that adjust fan speed automatically, optimizing both filtration and energy use.

Considering Airflow Rate and CFM

Airflow capacity determines how quickly a purifier can process a room's air. As a rule of thumb, look for a Clean Air Delivery Rate (CADR) that suggests 4-5 air changes per hour for your room size. For a 300 square foot bedroom with 8-foot ceilings, this typically means a purifier rated around 150 CFM. Don't be fooled by high CFM numbers alone - the filter must maintain HEPA efficiency at that airflow rate.

Assessing Filter Surface Area and Media

Filter design innovations have significantly improved real-world performance. Deep-pleated designs offer more surface area in compact units, while some premium models use progressive density media that's more open at the front (reducing airflow resistance) and denser at the back (enhancing filtration). These advances allow modern units to achieve better performance with less noise and energy use than older models.

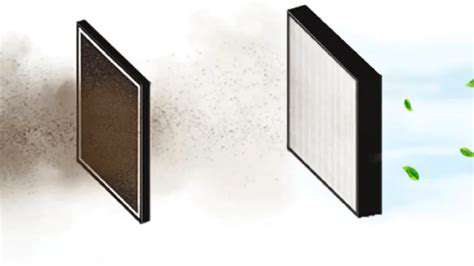

Evaluating Filter Life and Replacement Frequency

Filter lifespan depends heavily on usage environment. A unit in a pet-friendly home might need replacement every 6 months, while one in a low-dust environment could last 18 months. Many modern units include filter life indicators, but these are often just timers - visually inspecting the filter monthly provides the most accurate assessment. Some manufacturers now offer subscription services for automatic filter delivery when replacements are due.

Considering the Application and Intended Use

Special circumstances demand specialized filters. Homes with smokers should consider units with extra activated carbon. Allergy sufferers might benefit from filters with antimicrobial treatments. For wildfire smoke protection, look for units tested specifically for smoke particle removal - some perform better than others with these challenging particles. Always match the filter capabilities to your specific air quality concerns.

Analyzing Filter Dimensions and Compatibility

Before purchasing, measure not just the filter slot dimensions but also the available clearance for filter removal and installation. Some built-in systems require specific filter orientations or have tight tolerances. For aftermarket replacements, bring your old filter to the store for direct comparison - even small size discrepancies can cause leaks that bypass the filtration entirely. When in doubt, consult the equipment manual or manufacturer.

Understanding Filter Certifications and Standards

Beyond basic HEPA certification, look for additional validations like AHAM verification for residential units or ISO 14644 for critical environments. The California Air Resources Board (CARB) certification indicates compliance with strict ozone emission limits, important for electronic air cleaners. Energy Star ratings help identify efficient models. These certifications provide independent confirmation of manufacturer claims.

Disclaimer: All articles on this site are original, please do not reprint